- Phone: +86-318-8888385

- E-mail: bruce@yongber.com

PEM electrolysic Cell for Hydrogen & Oxygen Production

PEM electrolysis cell is widely used for hydrogen and oxygen production.

PEM electrolysis cell is an advanced product, which are lightweight, effective and environmental protection. It is widely used for producing hydrogen and oxygen through the electrolysis of pure water (without adding alkali). That's PEM technology. The SPE electrodes, as the core of cell, are highly active catalytic electrode with nearly zero distance between the electrodes, which is formed by integrating composite catalyst with and ion membrane with high electrolytic efficiency.

Top View of PEM electrolysis cell.

PEM electrolysis cell with silicon hose.

Front view of large PEM electrolysis cell

PEM electrolysis cell anode

Enlarged details of PEM electrolysis cell

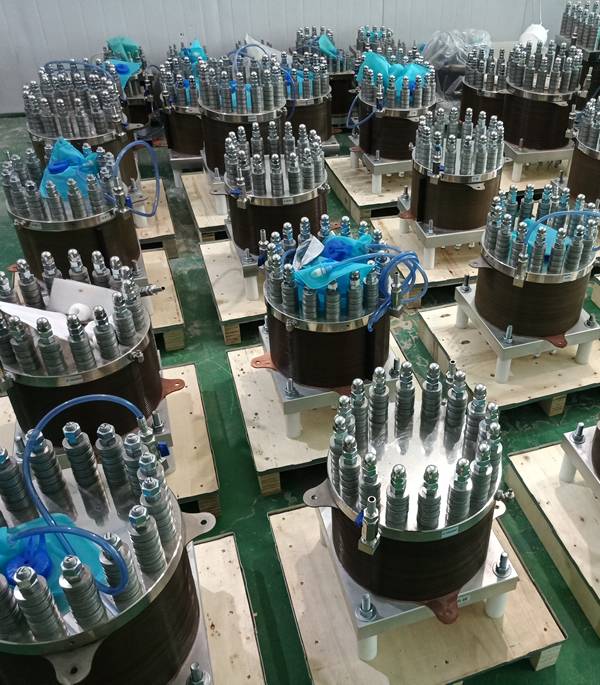

PPEM electrolysis cell warehouse storage

| PEMEC-300 | PEMEC-500 | PEMEC-1000 | |

|---|---|---|---|

| Working Voltage (DC) | 2.5 V | 5 V | 10 V |

| Working Current (DC) | 45 A | 36 A | 36 A |

| Gas output (ml/min) | H2: 300O2: 150 | H2: 500O2: 250 | H2: 1000O2: 500 |

| Diameter | 138 | 138 | 138 |

Features & Benefits

- Large current density.

- Low electrolytic voltage.

- High electrolytic efficiency.

Specification

| Model | Gas Flow |

|---|---|

| QLC-85A | 70 mL/min |

| QLC-85B | 150 mL/min |

| QLC-85C | 200 mL/min |

| QLC-85D | 300 mL/min |

| QLC-138A | 300 mL/min |

| QLC-138B | 600 mL/min |

| QLC-138C | 800 mL/min |

| QLC-138D | 1000 mL/min |

| QLC-175-25 | 1 Nm3/h |

| QLC-175-50 | 2 Nm3/h |

| QLC-330-30 | 2 Nm3/h |

| QLC-330-45 | 3 Nm3/h |

| QLC-660-30 | 10 Nm3/h |

| QLC-660-60 | 20 Nm3/h |

How to use?

- Remove the sealing film of water inlet and hydrogen water outlet. Erect the electrolyzer cell to flow out small amount of deionized water.

- Fasten the holder of electrolysis cell on suitable place with the M5 screws.

- Connect the water inlet and water outlet of the water storage tank with 6 mm (I.D.) × 9 mm (O.D.) silicon hose. And connect the oxygen water outlet and the recycled water inlet of water storage tank. In this way, the deionized water can be recycled after passing through the electrolytic tank.

- Connect the positive plate of the electrolyzer to the positive line of the power supply, and connect the negative plate to the negative line of the power supply. Tightly fasten them with M6 screws (when the screw is loose, heat will be generated and the electrode wire will be burned out).

- Connect the hydrogen outlet and hydrogen water inlet of the hydrogen-water separator. Be sure all the screws are tightly fastened to prevent air leakage.

Notice

- Electrolyzer water must be deionized water or double distilled water and the resistivity is larger than 1 MΩ/cm. Water that does not meet the standard will cause irreparable damage to the electrolyzer cell.

- When connecting the electrode wire, it must be absolutely right in right to right and negative to negative.

- The electrolyzer should not be prolonged in water shortage. When the electrolyzer cells are unloaded, a bit of deionized water or double distilled water should be injected into the electrolyzer.

Inquiry for Our Product

Hengshui Excellent Technology Co., Ltd

E-mail:

bruce@yongber.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.